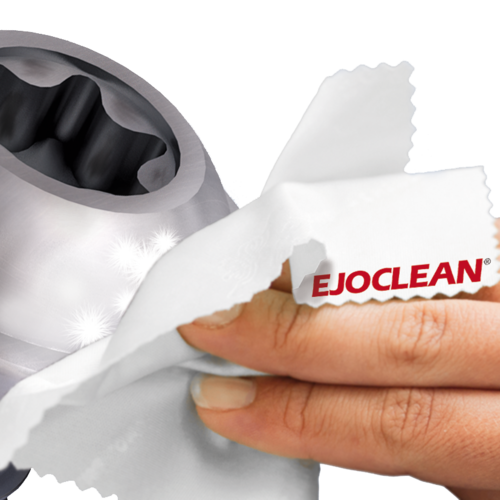

Technical cleanliness - EJOCLEAN®

Specification

-

Overview

- Grade 1 = largest acceptable particle* = 800 µm (recommended drawing specification: X = 800 µm acc.to VDA 19 / ISO 16232)

- Grade 2 = largest acceptable particle = 400 µm (recommended drawing specification: CCC = A (I-K00) acc.to VDA 19 / ISO 16232 or X = 400 µm acc. to VDA 19 / ISO 16232)

Hotline

Applications Engineer

Increased customer demands

The standards for the cleanliness of components have been increasing significantly, as even the smallest impurities on component surfaces can have serious consequences in many areas. The areas of possible impact on function or safety include visual defects, e.g. displays or headlight systems, as well as safety related influences such as unwanted contact of electronic systems.

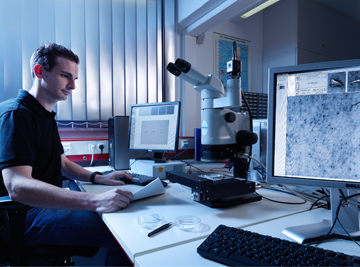

With the innovative EJOCLEAN® programme EJOT has been offering individual customer solutions to use „clean“ fasteners on the assembly line, in order to achieve the best possible cleanliness on component surfaces. To realise and monitor the cleanliness objectives, EJOT employs state of the art equipment and analysis technology.

Reliable processes with EJOCLEAN®

The process reliability of „technical cleanliness“ is guaranteed by modern systematic and statistic processes, as well as other measures.